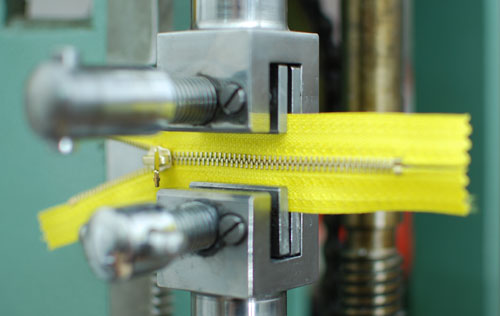

The process of zipper fatigue testing involves several key steps

The process of zipper fatigue testing involves several key steps. First, a sample of zippers is selected for testing. This sample should be representative of the entire production run and should include zippers of different sizes and styles. The zippers are then attached to a testing machine that is capable of applying a specified amount of force to the zipper pull.

The testing machine is programmed to open and close the zipper a certain number of times, typically between 10,000 and 50,000 cycles. During each cycle, the force applied to the zipper pull is measured and recorded. This allows testers to monitor the amount of stress that the zipper is experiencing and to identify any areas of weakness or fatigue.

After the testing is complete, the zippers are inspected for signs of wear and tear. This may include checking for broken teeth, bent or twisted components, or other signs of damage. The results of the testing are then analyzed to determine the zipper’s overall durability and to identify any areas where improvements can be made.